Engineering

Electrotechnics

Why automation

Effective solution tailored to you

We always take into account the nature of the operation, the range and the required performance, focusing on productivity and reducing errors.

PERFORMANCE, SAFETY, ERGONOMICS & RELIABILITY

No more chaotic manipulation. Everything has its system and is centrally managed. In addition, you can increase the accuracy of the performance by connecting robotic elements.

PRODUCTIVITY INCREASING

Don't waste your time and money. The logistics of the supply of input material to the finished product can flow without unnecessary downtime.

ERROR-FREE ASSEMBLY

Our automated workplace efficiently solves the operation of assembly and control elements of production lines. We rely on accuracy, performance and safety.

Receiving/assembly/processing/inspection/storage and dispatch

ROBOT ROTATION OF PRODUCTS

Assembly technology requires the assembled product assembly to rotate 180 ° C. Because the product is not firmly fixed on the mounting pad, a 3D camera is used to guide the robot. The grip of the product respects the permitted contact surfaces and forces.

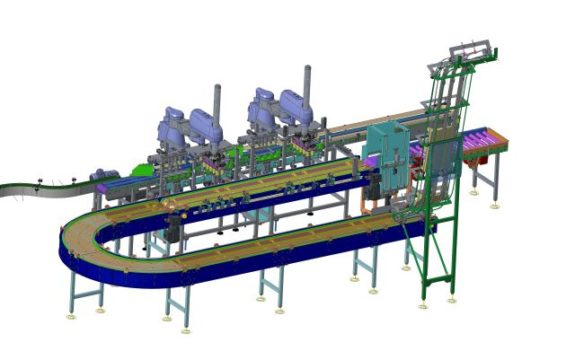

TRANSFORMER INSPECTION LINE

Roller conveyors, belt conveyors and other equipment are the basis of this transformer inspection line. High voltage test sections are equipped with certified conveyors with puncture resistance. The delivery includes transport pads with the possibility of settling and rotating products of various sizes.

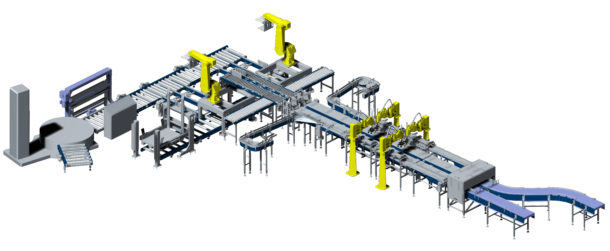

ASSEMBLY LINE OF ELECTRICAL MOTORS

The assembly lines are used for the assembly of electric motors with a maximum weight of 2,300 kg and 4,500 kg, respectively, transported on assembly pads. The weight distribution on the pad allows the use of roller chain conveyors with higher load capacity.