COCKPIT LINE FOR ŠKODA AUTO

For our long-term important customer ŠKODA AUTO we have delivered a conveyor line of assembly frames. Assembly of individual cockpit parts is carried out on this line.

It is a complete delivery from design, production, testing, installation and commissioning, including the control system.

TIME-LAPSE VIDEO

This time-lapse video shows an abbreviated video of the installation and commissioning of the cockpit assembly line.

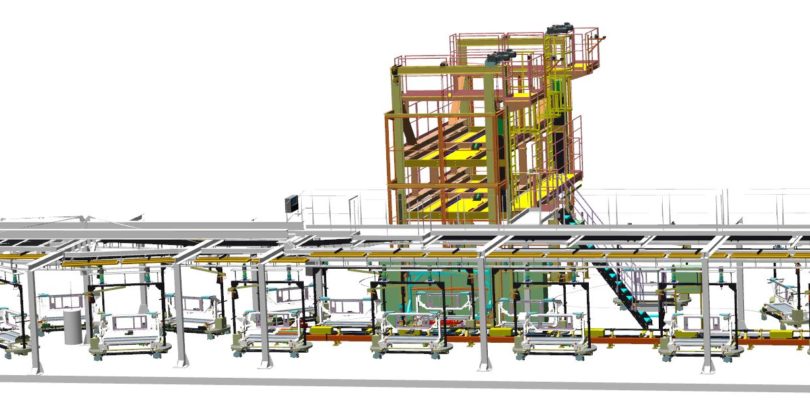

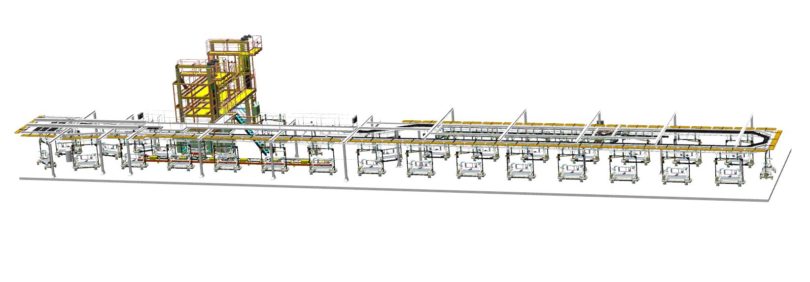

COCKPIT ASSEMBLY LINE

PARTS OF THE ASSEMBLY LINE

Pulling conveyor

The pulling conveyor of the cockpit assembly line is designed to ensure the movement of assembly trolleys with assembly frames in the cockpit assembly line and it is used to move the trolleys among assembly workplaces.

- Total conveyor length: 124 m

Assembly trolleys

The assembly trolleys are designed for the inter-operation transport of cockpits for individual assembly operations. The movement of the trolleys is ensured by means of pulling lugs firmly attached to the pulling chain on the steel structure of the suspended pulling conveyor.

- Dimensions of the trolley: 2 350 × 980 × 2 605 mm (length × width × height)

- Max. trolley load: 230 kg

Mounting frames

The mounting frames are designed to handle the cockpit during assembly, allowing the desired position for assembly to be set. During assembly, the assembly frame is placed on the assembly trolley.

- Frame dimensions: 790 × 1700 × 950 mm (width × length × height)

- Max. frame load: 80 kg

Accelerating chain conveyor

The accelerating chain conveyor is designed for transporting trolleys with assembly frames in the cockpit assembly line. It is used to move trolleys between the assembly circuit itself and the transfer point.

- Conveyor length: 16,5 m

- Movement speed: 2 – 10 m/min

Internal test circuit

The internal test circuit is designed for output diagnostics of the correct functioning of all electrical components of the assembled cockpits and consists of four test trolleys.

- Test circuit length including service track: 18 m

- Maximum load of the test trolley: 100 kg

Control measuring device for assembly frames

The line also includes an inspection measuring device for dimensional inspection of individual assembly frames.

CONTROL SYSTEM

The delivery of the entire large-scale line is including the SW control system designed by us, the production of switchboard cabinets and the subsequent installation of the wiring and overall commissioning.

The control system meets the current requirements. The control functions are provided by a Siemens S7-1500 series PLC.

The industrial control system of the assembly line is connected to the control system of the downstream devices by means of a PN/PN copler.

The operator interface for routine operations are pushbuttons and annunciators. For other operations, a graphical touchscreen is provided which allows a wealth of diagnostic and status information to be shared with the operator at the plant site, even using graphical objects.

The PLC of the assembly oval is also connected to the customer’s regular LAN. There are typical data structures that are accessible via this connection for remote management and visualization at the so-called higher control level.

As there were only two weeks to build this line, every minute was precious to us. We prepared accordingly.

The entire line was first assembled and carefully tested in our TMT hall.