EFFICIENT SORTING LINE IN THE DISTRIBUTION CENTRE

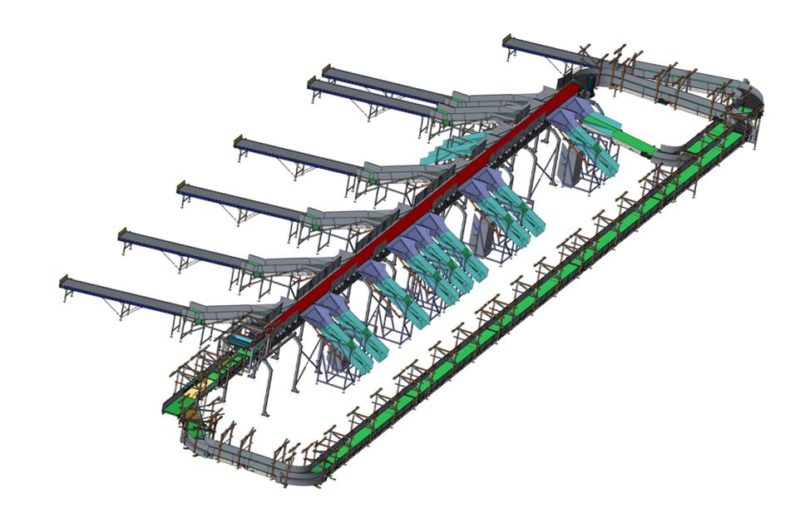

Implementation of an automated sorting line for largest logistics centre of Alza.cz in Chrášt’any.

The project includes the installation of a powerful sorter, which allows sorting up to 5,800 shipments per hour.

An extensive conveyor system is installed for all handling and supply of shipments.

POWERFUL SORTER (INTRALOX)

- Capacity max. 5 800 pcs/hr.

- 5x IN + 18 OUT/sorter

- Sorting of envelopes (bags), boxes, plastic crates

DESCRIPTION – SORTING OF SHIPMENTS

The transport part of the sorter is designed for a capacity of up to 5 800 pcs/hr. The backbone route, including the loop back, is equipped with frequency converters for optimum adjustment of the product flow. The infeed section allows products to be aligned to one side and a cascade of conveyor belts adjusts any minimum spacing for correct subsequent reading.

Barcode reading is from one side and from the top. In the case of a product unsuitable for transport into the KLT, the barcode on the side of the KLT is read in priority. When the given slip is filled or the no.k. is not read, the given product crosses the sorter part and connects back to the backbone route in front of the sorter. All these products are internally managed as NOREAD and sent to the error branch if not read again. The transported products are oriented so that the length of the input edge does not exceed 500 mm.

Servise

We provide both regular and emergency service to the line in 24/7 mode.

Is this an interesting project for you? If you have any questions, you can call or write to us.