Distribution Centers & Warehouses

E-commerce

Why automation

EFFICIENT SOLUTION FOR YOU

Storage, picking and packing? We always take into account the nature of the operation, the range and the required performance with a focus on productivity and avoiding errors.

ERROR-FREE

Inspection at every step and a reliable ordering system will guarantee you flawless delivery of your shipments.

The perfect system

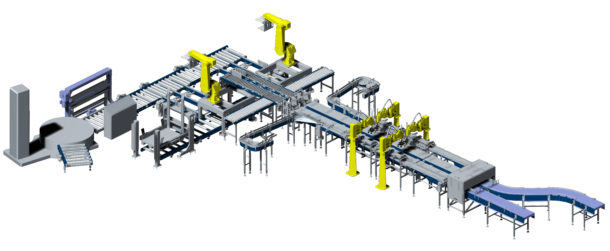

No more chaotic reloading and picking. Everything has its own system and is centrally controlled. Your employees become indispensable coordinators of the entire system. In addition, you can increase performance accuracy by connecting TMT robotic components.

EASY HANDLING AND LOGISTICS

With us, you will optimally serve the warehouse in automatic mode. We solve unattended handling and storage of crates, cartons, envelopes and other transport units.

Distribution Centers & Warehouses, E-commerce

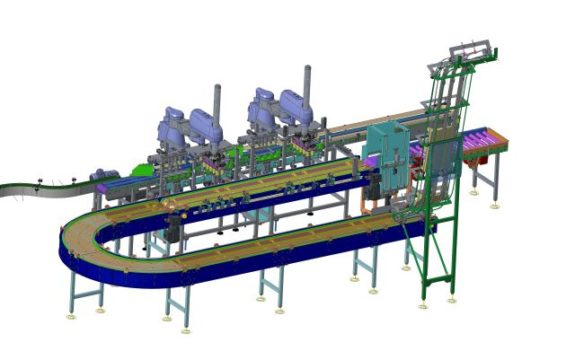

SPIRAL TRAYS

The spiral gravity trays are connected to the shipment sorter. They take advantage of the vertical difference in the conveyor route and act as a reliable gravity tray connecting the storey floor.

Puller Sorter

The sorting line with one-sided roller puller sorters is designed for a maximum of 3,000 shipments/hour. Shipment size from 200 to 800 mm.

pulley

Expedition „station“

Finished shipments are transported to the expedition by driven roller conveyors. Shipments are sorted into individual shipping branches according to the bar codes located on the top of the shipment.

Main parts of conveyor routes

Checkweigher

Shipment identification

Crate stacker / destacker

Packaging workplace

Folding sections

Sorting module