Food Industry

Why automation

EFFICIENT CUSTOM SOLUTIONS

We always take into account the nature of the operation, the range and the required performance with a focus on productivity and error reduction.

PERFORMANCE, ERGONOMICS, SECURITY AND RELIABILITY

Make an end to chaotic manipulation. We give everything a system and provide central management. By connecting TMT robotic elements, you also increase the accuracy.

PRODUCTIVITY INCREASE

Don't waste your time or money. The logistics of feeding the input material to the finished product flows without unnecessary downtime.

ERROR-FREE ASSEMBLY

Our automated workplace efficiently solves the smooth running of production lines. We rely on accuracy, performance and safety.

Production

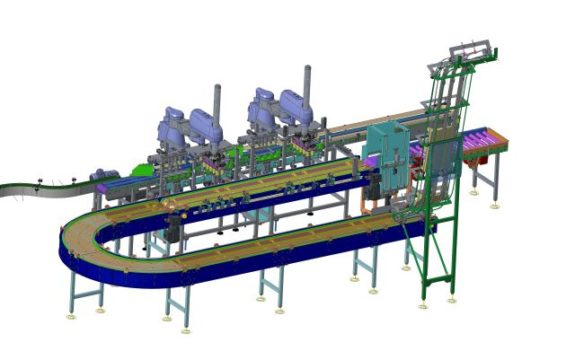

SORTING OF MÜSLI BARS

The line is designed to transport and feed müsli bars from production machines to the packaging machine. The solution is based on stainless steel belt conveyors and pneumatic shifters. The control system communicates with the production machines and the packaging machine.

TRANSPORT OF popsicles

For the transport of already packaged popsicles, we created a conveyor line in the refrigeration plant, which significantly simplified the work and, in particular, saved production time.

PIZZA TRANSPORT

We also implemented conveyors designed for direct transport of semi-finished and finished products. They also included the dismantling of production machines and their commissioning with connecting conveyors.

Packing & Expedition

INTEROPERATIONAL TRAY

The installation of an intermediate storage tray for baby food compensates for the power fluctuations of the following technological equipment. The basis of the solution is a set that effectively combines conveyors with plastic modular belts.

INSERTING CUPS

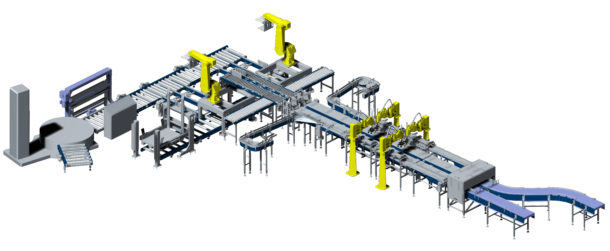

PALLET PALLETIZATION

The final part of the robotic line is the palletization of stacked paper trays with plastic cups. An interesting solution is the robot’s gripper, which picks up incoherent stacks. The palletizing terminal includes pallet conveyors, plate feed routes, stackers, palletizing robots and pallet fixing machines.

wrapping machine

PALLETISATION OF PAPER PLATES

The final part of the robotic line is the palletization of stacked paper trays with plastic cups. An interesting solution is the robot’s gripper, which picks up incoherent stacks. The palletizing terminal includes pallet conveyors, plate feed routes, stackers, palletizing robots and wrapping machine for pallet fixation.

CAN CONVEYORS

The conveyor connection between the filling machines and the group packaging is performed by conveyors with plastic modular belts.

TRANSPORTATION OF MATURE BOXES

The four-storey ripening cellars of the new cheese factory have a capacity of five thousand ripening boxes, which can hold three thousand tons of cheese. For relocation during the ripening process between the individual ripening cellars, we have installed a conveyor system with lifting sections, roller and chain conveyors.